2026 Aluminum Composite Panel Trends |

2026-01-18

.gtr-container-acp7f3d9e {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

max-width: 800px;

margin: 0 auto;

padding: 20px;

box-sizing: border-box;

}

.gtr-container-acp7f3d9e p {

font-size: 14px;

margin-bottom: 1em;

text-align: left !important;

}

.gtr-container-acp7f3d9e-intro {

margin-bottom: 2em;

font-size: 14px;

text-align: left !important;

}

.gtr-container-acp7f3d9e-section {

margin-bottom: 2em;

}

.gtr-container-acp7f3d9e-section-title {

font-size: 18px;

font-weight: bold;

color: #0056b3;

margin-top: 1.5em;

margin-bottom: 1em;

text-align: left !important;

}

.gtr-container-acp7f3d9e-list {

list-style: none !important;

padding-left: 20px;

margin-bottom: 1em;

}

.gtr-container-acp7f3d9e-list li {

position: relative;

padding-left: 20px;

margin-bottom: 0.8em;

font-size: 14px;

text-align: left !important;

}

.gtr-container-acp7f3d9e-list li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 1.2em;

line-height: 1;

}

.gtr-container-acp7f3d9e-conclusion-title {

font-size: 18px;

font-weight: bold;

color: #0056b3;

margin-top: 2em;

margin-bottom: 1em;

text-align: left !important;

}

.gtr-container-acp7f3d9e-conclusion-text {

font-size: 14px;

margin-bottom: 1.5em;

text-align: left !important;

}

.gtr-container-acp7f3d9e-keywords {

font-size: 14px;

color: #666;

margin-top: 2em;

text-align: left !important;

}

@media (min-width: 768px) {

.gtr-container-acp7f3d9e {

padding: 30px;

}

.gtr-container-acp7f3d9e-section-title {

font-size: 18px;

}

.gtr-container-acp7f3d9e p,

.gtr-container-acp7f3d9e-list li {

font-size: 14px;

}

}

In 2026, the global construction industry witnessed a material revolution under the dual forces of net-zero emissions and digitalization. Aluminum Composite Panel (ACP), as the core carrier of the intelligent building envelope, is reshaping industry standards through AI collaborative design systems, carbon capture coating technologies, and modular recycling systems. Based on the latest international building materials data and project cases, this article analyzes the technical paths and market landscape of ACP in the next three years.

1. Zero-Carbon Breakthrough: ACP Full-Chain with Traceable Carbon Footprint

By 2026, the EU's "Carbon Neutral Building Products Act" (CPND) will mandate that building materials disclose their full-cycle carbon footprint. Industry leaders have achieved:

Green hydrogen for aluminum smelting: Carbon emissions are reduced by 85% compared to traditional processes, and it is applied to the "Green Ring" curtain wall project of Apple's Singapore headquarters.

Biobased core material: Composed of recycled marine plastics and plant fibers, it has received the UL Cradle to Cradle Platinum certification;

Blockchain traceability system: For each square meter of the board, the source of raw materials and carbon footprint data can be queried through a digital passport.

2. Intelligent Evolution: Responsive Skin and AI-Assisted Design

Dynamic Optical ACP: Incorporating electrochromic microcapsules, the transparency of the curtain wall can be automatically adjusted according to the intensity of sunlight (41% energy savings in Microsoft's Seattle "Photosynthesis Tower" project);

AI Texture Generation Engine: By inputting architectural coordinates, environmental data and cultural symbols, it can generate regionally adapted surface patterns (the facade of the GCL Digital Art Center in Shanghai has already been applied);

Self-healing nano-coating: Scratches can be automatically repaired within 24 hours, reducing maintenance costs by 60%.

3. Market Reconfiguration: Dual Output of Technology and Capacity in the Asia-Pacific Region

The 2026 industry report states:

Technological superiority: Chinese enterprises hold 62% of the global patents for mineral fireproof core materials. The first ACP international standard (ISO 23678:2025) was jointly formulated by China.

Capacity upgrade: The "Smart Panel Factory" in India has adopted a full-process robot production system, reducing the delivery cycle for custom orders to just 72 hours.

New application scenarios: Space building test chamber (ACP-Mars project), breakthroughs achieved in the verification of deep-sea data center shell materials.

4. Circular Revolution: Urban Mines and Modular Secondary Utilization

Disassembly Technology Innovation: The laser separation technology of German company KreiselTech can achieve an ACP recovery purity of up to 99.7%.

Urban renewal project: In the renovation of the old financial district of London, 87% of the retired ACP panels were processed and used for the facades of new social housing buildings.

Subscription-based service model: The manufacturer offers "facade as a service". After the lease term expires, the panels are retrieved by the manufacturer for recycling and reprocessing.

5. Risk Warning and Compliance Outlook

Green premium narrows: The zero-carbon ACP price has approached that of traditional materials, and it is expected to reach parity by 2027;

Regulatory upgrade: The new regulations of UL 2850 in the United States will mandate that ACPs undergo extreme climate simulation tests (-50°C to 120°C cycles);

Biological safety standards: The World Health Organization will release a guideline for classifying the antibacterial performance of building surface materials in the third quarter of 2026.

Conclusion

Aluminum composite panels have entered the "material as a service" era. The core value in 2026 is not only the performance parameters, but also its ability to integrate as a carrier of the building carbon account, a node of urban resources, and a human-machine interaction interface. In the next three years, ACP products that do not integrate digital twins and circular traceability functions will gradually withdraw from the mainstream market.

Keyword optimization matrix

View More

Fire Proof PVDF ACP aluminum composite panel for building curtain wall and Urban renewal

2026-01-17

.gtr-container-xyz789 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

font-size: 14px;

line-height: 1.6;

color: #333;

padding: 15px;

max-width: 100%;

box-sizing: border-box;

margin: 0 auto;

}

.gtr-container-xyz789 p {

margin-bottom: 1em;

text-align: left !important;

}

.gtr-container-xyz789 .gtr-section {

margin-bottom: 25px;

padding-bottom: 15px;

border-bottom: 1px solid #eee;

}

.gtr-container-xyz789 .gtr-section:last-child {

border-bottom: none;

margin-bottom: 0;

padding-bottom: 0;

}

.gtr-container-xyz789 .gtr-heading-main {

font-size: 18px;

font-weight: bold;

margin-bottom: 15px;

color: #0056b3;

text-align: left;

}

.gtr-container-xyz789 .gtr-heading-section {

font-size: 16px;

font-weight: bold;

margin-top: 20px;

margin-bottom: 10px;

color: #0056b3;

text-align: left;

}

.gtr-container-xyz789 .gtr-heading-subsection {

font-size: 14px;

font-weight: bold;

margin-top: 15px;

margin-bottom: 8px;

color: #0056b3;

text-align: left;

}

.gtr-container-xyz789 .gtr-sub-description {

font-style: italic;

margin-bottom: 15px;

color: #555;

text-align: left;

}

.gtr-container-xyz789 .gtr-subsection {

margin-bottom: 15px;

}

.gtr-container-xyz789 ol,

.gtr-container-xyz789 ul {

list-style: none !important;

margin: 0;

padding: 0;

}

.gtr-container-xyz789 ol {

counter-reset: list-item;

}

.gtr-container-xyz789 ol li {

position: relative;

padding-left: 30px;

margin-bottom: 8px;

counter-increment: none;

text-align: left !important;

list-style: none !important;

}

.gtr-container-xyz789 ol li::before {

content: counter(list-item) "." !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-weight: bold;

width: 25px;

text-align: right;

}

.gtr-container-xyz789 ul li {

position: relative;

padding-left: 20px;

margin-bottom: 8px;

text-align: left !important;

list-style: none !important;

}

.gtr-container-xyz789 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 1.2em;

line-height: 1;

}

@media (min-width: 768px) {

.gtr-container-xyz789 {

padding: 25px 40px;

max-width: 960px;

}

.gtr-container-xyz789 .gtr-heading-main {

font-size: 20px;

}

.gtr-container-xyz789 .gtr-heading-section {

font-size: 18px;

}

}

Key Trend: There is a structural shortage in the upstream PVDF resin market.

This directly affects the cost and supply of PVDF coatings, and is currently the most notable industry variable to be monitored.

Trend Dimension

Specific Impact and Analysis

Supply Side:Control

Headquarter Companies'停产: The Wanma Company, which holds over 65% of the domestic market share for coating-grade PVDF, will cease production by the end of 2025, directly causing a tightening of market supply. Many companies then raised their prices.

Strict Raw Material Control: The key raw material R142b for producing high-end PVDF is subject to strict quota control, limiting the release of effective production capacity.

Demand Side: Pull from the Lithium Battery Industry

With the rapid growth of the new energy vehicle and energy storage industries, the demand for lithium battery-grade PVDF (used in battery adhesives) remains strong, with a projected year-on-year growth rate of up to 25% in 2026. This has led to a greater concentration of PVDF production towards the high-profit lithium battery sector.

Price Trend

Affected by the above factors, the market presents a "total supply is loose, structural tightness is increasing" pattern. Ordinary products have sufficient supply, but high-quality PVDF for high-end building coatings and lithium batteries may experience structural price increases. As of December 2025, the highest market price has reached 56,000 yuan per ton.

PVDF ACP Terminal Market: Stable Growth and Diversification Coexist

Despite fluctuations in the upstream, PVDF ACP still maintains a stable base in the terminal markets such as building facades, etc., thanks to its performance advantages.

Stable market position:

In the global aluminum composite panel market, PVDF-coated products account for 65.89% of the revenue share, and are expected to continue to grow at a compound annual growth rate of approximately 6.70%. They are the absolute top choice for the high-end market.

Core logic of growth:

Its growth is mainly attributed to its extremely long service life (20-25 years) and cost advantages throughout the entire lifecycle. It is particularly favored by high-end commercial buildings and public infrastructure projects.

Key compliance trend:

Global (especially in Europe and America) fire safety regulations continue to tighten, driving the adoption of A2-level fire-resistant mineral core as the standard configuration for high-rise buildings. When choosing PVDF ACP, it is essential to simultaneously confirm the fire resistance grade of the core material to comply with local building regulations.

View More

Aluminum composite panels with flatness, rigidity, lightweight and formability

2026-01-14

.gtr-container-q9w8e7r6 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

padding: 16px;

line-height: 1.6;

box-sizing: border-box;

max-width: 100%;

overflow-x: hidden;

}

.gtr-container-q9w8e7r6 p {

font-size: 14px;

margin-bottom: 1em;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-q9w8e7r6 p:last-child {

margin-bottom: 0;

}

.gtr-container-q9w8e7r6 .gtr-highlight {

font-weight: bold;

color: #0056b3;

}

.gtr-container-q9w8e7r6 .gtr-brand {

font-weight: bold;

font-size: 16px;

color: #007bff;

}

.gtr-container-q9w8e7r6 .gtr-origin {

font-style: italic;

color: #666;

margin-top: 1.5em;

margin-bottom: 1.5em;

}

@media (min-width: 768px) {

.gtr-container-q9w8e7r6 {

padding: 24px;

max-width: 800px;

margin: 0 auto;

}

.gtr-container-q9w8e7r6 .gtr-brand {

font-size: 18px;

}

}

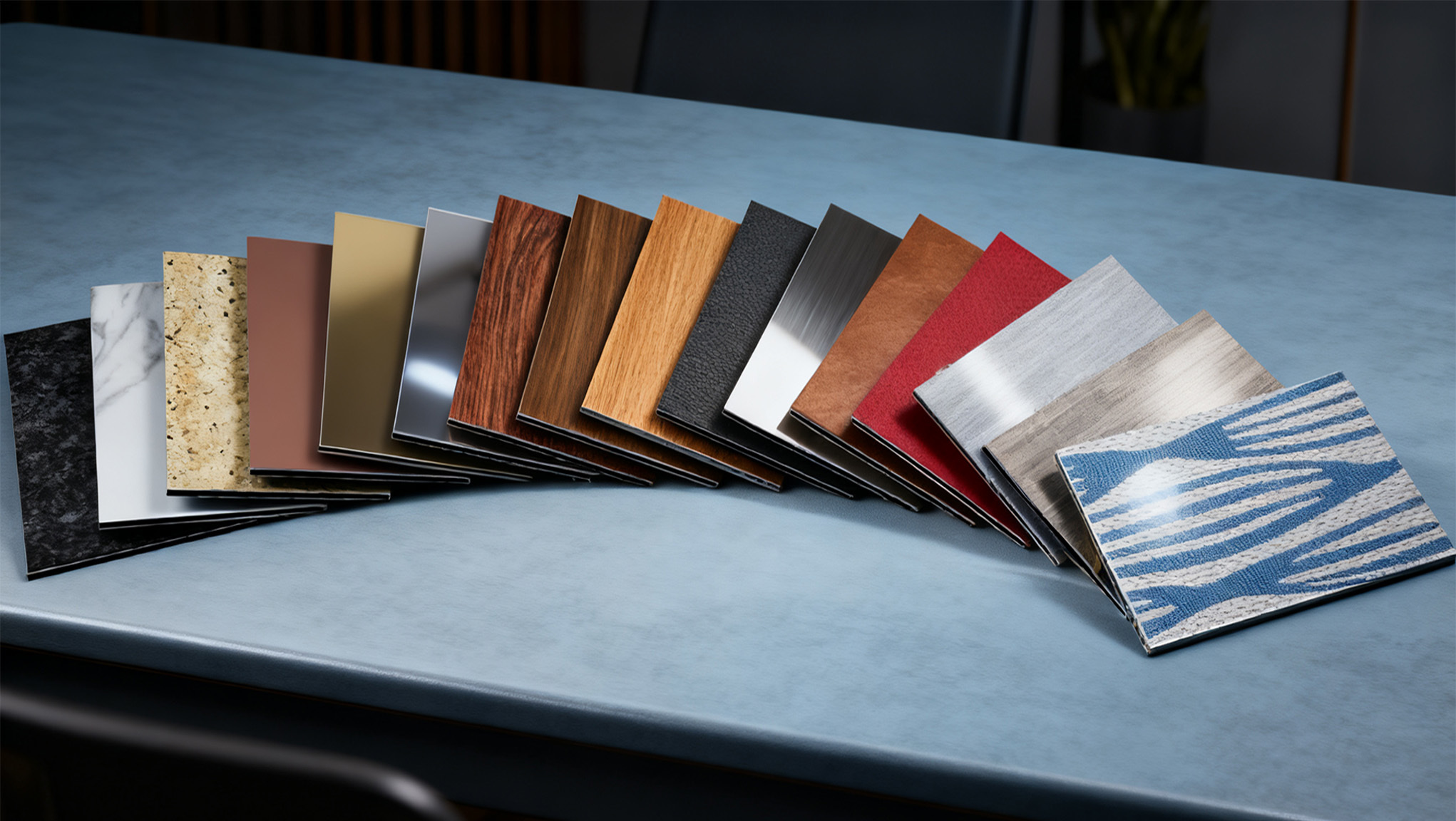

As a preferred material for both indoor and outdoor design, our factory's products seamlessly extend colors from indoors to outdoors, and are highly favored for their outstanding flatness, strong plasticity, durability and ease of processing.

The products are made in China.

The brand JIXIANGSIJI offers a variety of specifications, cutting-edge colors and surface treatments, covering both standard and customized options. A rich product range helps create inspiring architectural ideas and brings design to life.

View More

Overview of the Core Market Conditions of Aluminum Composite Panels in January 2026

2026-01-12

.gtr-container-k7p2q9 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

padding: 20px;

line-height: 1.6;

text-align: left;

}

.gtr-container-k7p2q9-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 15px;

color: #1a1a1a;

text-transform: uppercase;

letter-spacing: 0.5px;

text-align: left !important;

}

.gtr-container-k7p2q9-subtitle {

font-size: 14px;

margin-bottom: 20px;

color: #555;

border-bottom: 1px solid #eee;

padding-bottom: 10px;

text-align: left !important;

}

.gtr-container-k7p2q9-item {

font-size: 14px;

margin-bottom: 15px;

padding-left: 15px;

position: relative;

text-align: left !important;

}

.gtr-container-k7p2q9-item::before {

content: "•";

color: #007bff;

position: absolute;

left: 0;

font-weight: bold;

font-size: 16px;

line-height: 1;

top: 0;

}

.gtr-container-k7p2q9-highlight {

font-weight: bold;

color: #0056b3;

}

@media (min-width: 768px) {

.gtr-container-k7p2q9 {

padding: 30px 40px;

}

.gtr-container-k7p2q9-title {

font-size: 20px;

}

.gtr-container-k7p2q9-item {

margin-bottom: 18px;

}

}

overview of core market conditions

Details of the indicators

The global market size is approximately 36.12 billion US dollars in 2025.

The future growth is expected to reach 71.05 billion US dollars by 2035, with a compound annual growth rate of approximately 7% from 2026 to 2035.

The Asia-Pacific region is the largest market, accounting for approximately 38% of the global share. China is a core producer and consumer.

The product price range (for reference) : The Chinese market offers a wide variety of products with a relatively broad price range, approximately ranging from 7 to 20 US dollars per square meter.

The main application fields are building curtain walls (especially commercial buildings), which are the primary demands. Meanwhile, the demands in areas such as digital advertising fences and vehicle interiors for transportation are growing rapidly.

View More

Characteristics of the main regional markets for aluminum composite panels

2026-01-12

.gtr-container-x7y8z9 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 16px;

max-width: 100%;

box-sizing: border-box;

margin: 0 auto;

}

.gtr-container-x7y8z9-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 16px;

text-align: left !important;

color: #0056b3;

}

.gtr-container-x7y8z9-intro {

font-size: 14px;

margin-bottom: 12px;

text-align: left !important;

}

.gtr-container-x7y8z9-paragraph {

font-size: 14px;

margin-bottom: 12px;

text-align: left !important;

}

.gtr-container-x7y8z9-paragraph strong {

font-weight: bold;

color: #0056b3;

}

@media (min-width: 768px) {

.gtr-container-x7y8z9 {

padding: 24px 32px;

max-width: 800px;

}

.gtr-container-x7y8z9-title {

font-size: 20px;

margin-bottom: 20px;

}

.gtr-container-x7y8z9-intro,

.gtr-container-x7y8z9-paragraph {

font-size: 15px;

margin-bottom: 16px;

}

}

Characteristics of the main regional markets for aluminum composite panels

Market drivers and product preferences vary in different regions:

The Asia-Pacific region (core market) : Growth is mainly driven by rapid urbanization and infrastructure investment in countries such as China and India. China has a complete industrial chain and a large number of manufacturers, and its products offer high cost performance.

North America and Europe: Market growth is driven by green building standards and increasingly strict fire safety regulations. There is a clear demand for high-performance products such as high-end PVDF coatings and A2-level fire-resistant mineral cores, and the product premium is relatively high.

View More